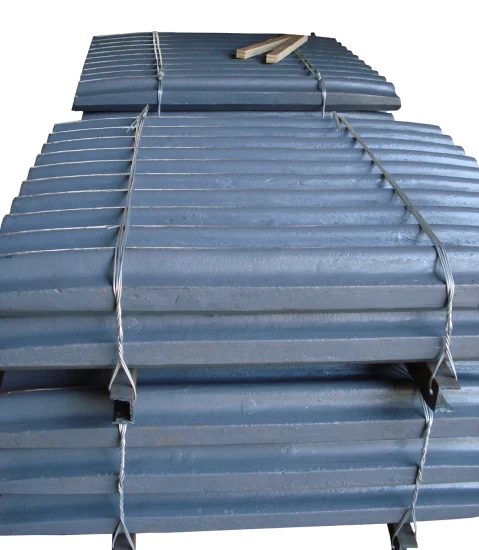

High Manganese Wear Parts Mn13cr2 Jaw Plates Jaw Crusher Parts

Basic Info

| Certification | ISO 9001:2008 |

| Standard | ASTM |

| Surface Treatment | Polishing |

| Manufacturing Process | Casting |

| Material | Alloy Steel |

| Quality | High |

| Application | for Jaw Crusher to Replace |

| Teeth | Square, Round |

| Transport Package | Iron Frame |

| Specification | Mn13Cr2, Mn18Cr2 |

| Origin | China |

| HS Code | 8474900000 |

| Production Capacity | 10000ton Per Year |

Product Description

High Manganese Wear Parts Mn13Cr2 Jaw Plates Jaw Crusher Parts

Introduction of Jaw Crusher Parts

Jaw plate is manufactured with super high manganese steel, therefore it has a service life 50~100% longer than those made of traditional high manganese steel. Every model of PE series jaw crushers is tested for shock, stress, strain, thermal loading, deformation, vibration and noise under a wide range of load conditions. The special processing techniques ensure that our jaw plate has leading performance:

1)Using cold processing hardening technology, the hardness is improved.

2)Water toughening technology to avoid making the performance poor during the process of natural phase change.

We manufacture an extensive range of wear and spare parts in China for the worlds most popular crushing brands, like the spare parts for the below crushers.

Crusher type | Model | Spare parts |

Jaw crusher | C80, C96, C100B, C105, C106, C110, C116, C125, C140, C145, C160, C200 | Jaw plates, Cheek plates |

JM806, JM907, JM1108, J1175, JM1206, JM1208, JM1211, JM1312, JM1511, JM1513 |

Features of Jaw Crusher Parts

1) Material: high manganese steel:Mn13Cr2, Mn18Cr2, etc;

2) Use: Machinery in metal recovery smash, mine, metallurgy, chemical industry, cement, petroleum etc.

3) Production quality testing: High frequency infrared carbon & sulfur analyzer, Metallographic microscope, Machinery performance testing equipment, Hardness testing equipment, Ultrasonic inspection equipment

4) Easy installation: The anti-abrasion block is a semi-permanent part, which is easy for replacement.

Chemical composition of Jaw Crusher Parts

High Manganese Casting Material Chemical Composition | |||||||

Code Elem. | C | Mn | Si | Cr | Mo | P | S |

ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.5 | - | ≤0.09 | ≤0.04 |

ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

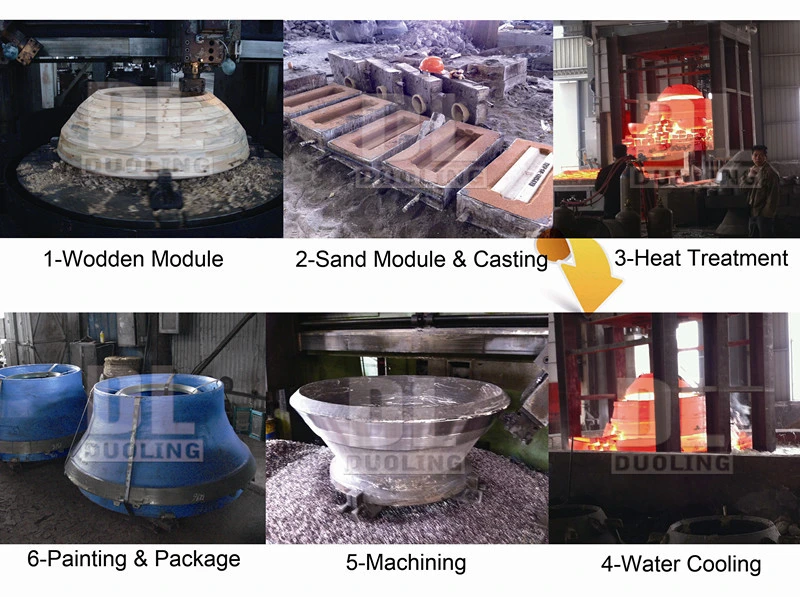

Production Process of Crusher Wear Parts